Tips for Contractors: The Perfect Vinyl Flake Epoxy Floors

Vinyl flake epoxy floors are simpler than ever.

Are you familiar with vinyl flake epoxy flooring? If not, you're missing out! It's a cost-effective and customer-approved option that contractors and DIY enthusiasts should know about. At Epoxy Classes, we're experts in flooring installations and stay up-to-date on industry standards. We're here to share our knowledge on vinyl flake epoxy floors with you.

Keep reading to learn about the key ways you can improve any vinyl flake epoxy floor installation!

Vinyl Flake Epoxy Floors 101 & Tips

Nowadays, an increasing number of homeowners are in search of a fast and dependable flooring solution for their garages. They'll go to Google, they'll search for "one day garage", but what exactly do they come across? Flake epoxy garage floors.

Vinyl flake epoxy floors are a flooring contractor's dream solution. They're increasingly popular, affordable to install and have quick turnaround times! Any vinyl flake epoxy flooring installation typically entails applying two or more layers of epoxy resin infused with vinyl chips or flakes, followed by a clear topcoat. The chips themselves are available in a range of hues and dimensions, and contractors should use superior-quality vinyl flakes to massively improve the floor's durability.

Flake epoxy flooring service can lead to a multitude of benefits for any flooring business. Not only will your customers be satisfied with the added durability and style, but you will love the extra profits that come with flake.

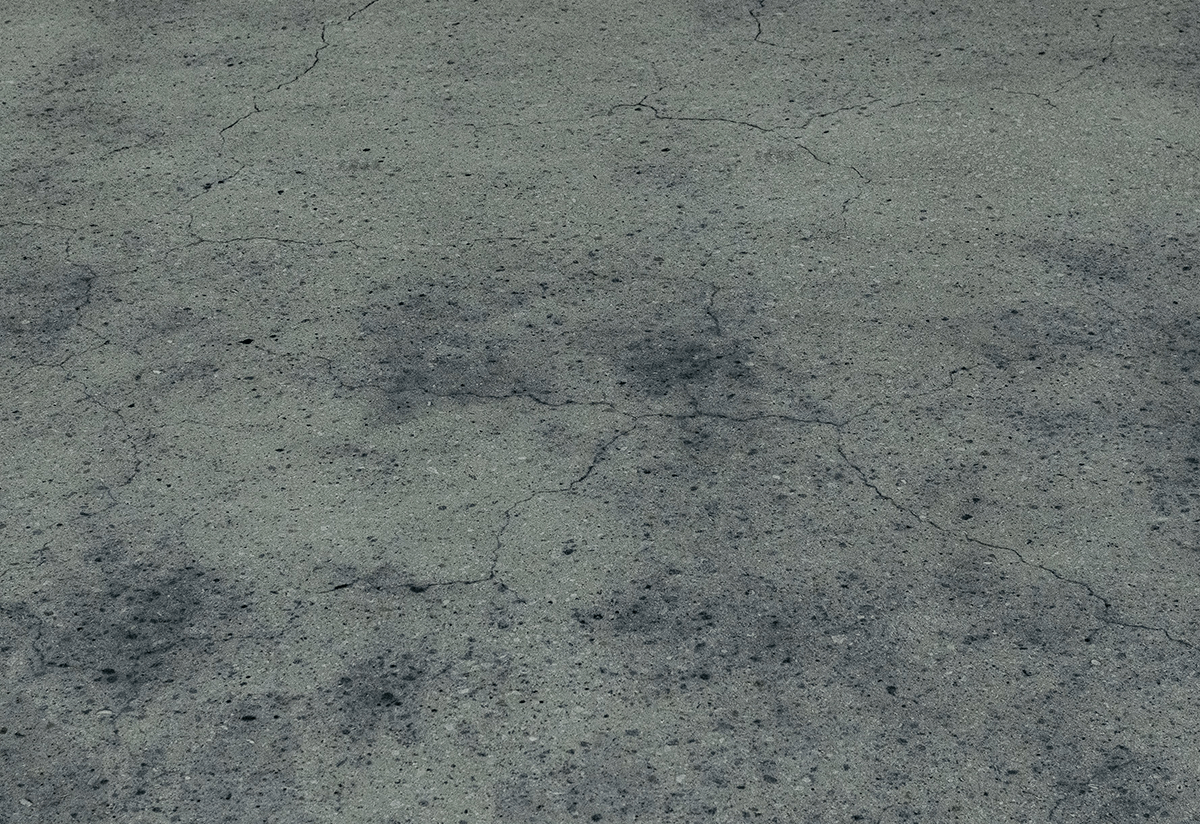

Surface Prep: Often Forgotten, Often Essential

Effective surface preparation is critical to achieving a robust and long-lasting bond when installing an epoxy floor. To ensure durability, it's imperative to first clean the floor with a gentle cleaner, remove all debris, and repair any cracks or damage in the foundation. By meticulously prepping the subfloor, you'll not only create a visually appealing epoxy flooring, but also extend its lifespan for years to come. Do you want some tips on how to make surface preparation as seamless as possible? Keep reading to find out:

-

Properly assess the surface: Inspect the surface for any cracks, holes, or other types of damage. Make sure to repair these issues before moving forward with the installation.

-

Take your time: Don't rush the surface preparation process. The more time and effort you put into prepping the subfloor, the better the outcome will be.

-

Test for moisture: Before installing the epoxy flooring, make sure to test the surface for moisture. If the subfloor is damp, it can prevent the epoxy from bonding correctly, leading to premature failure.

Surface preparation is a crucial step in strong and durable bonds for your epoxy flooring installation. Between the above tips and patience to properly prep the foundation of your clients' new floors, you'll be well on your way to achieving a beautiful finished product that will stand the test of time.

The Right Tools Make All the Difference

Any contractor worth their salt knows the right toolkit is crucial to a successful epoxy floor installation. With the wide range of tools available, at different price points, saying they'll solve all your problems, it can be tough to navigate. Here are some tips to guide you in wading through the market for the right tools:

-

Invest in quality tools: An investment in high-quality tools may cost more initially, but it's always worth it. Your tools will last longer, and your results will be crisper time after time.

-

Use a diamond-tipped grinder: A diamond-tipped grinder is an excellent tool for removing existing coatings, and preparing the surface for an epoxy installation.

- Protect yourself & workers: For any flooring business to be sustainable, you need to have the right safety equipment. From industry-standard vacuums to personal protective equipment, you need safety gear.

The right tools and equipment will more often than not make a successful and long-lasting epoxy installation a guarantee. So, take the time to invest in quality tools, do your research and build better floors!

Vinyl Flake Epoxy Floors: Application 101 & Tips

Proper application and installation are critical to achieving a beautiful and durable vinyl flake epoxy floor. There are some basic universal tips you should know, like follow the manufacturer's instructions, or that you should work in sections on larger projects, but we want to help you with things you might not know. From polished concrete to vinyl flake, you can always improve. Here are some tips to guide you through the process:

At EpoxyETC, we offer high-quality resin resources packaged together for your convenience. Check out our Flake Epoxy kits and DIY kits to get started on your project. Having the right tools and materials on hand will help ensure a successful and beautiful vinyl flake epoxy floor installation.

It's important to follow some key tips during the application and installation of vinyl flake epoxy floors. First, make sure to allow each layer enough time to cure and dry before you move to the next layer. You never want a floor to fail before it's even done. So, ensure a strong and durable bond between each layer with some patience. Secondly, air bubbles can be reduced by using a hair dryer or a source of targeted heat.

Another helpful tip is to use spiked shoes to navigate around the job site without leaving footprints on the surface. And to avoid having to redo any layers, strive to get each layer right the first time through. Finally, consider using separate layers of polyaspartic and traditional resin to cut down on labor, resource costs, and installation time.

Vinyl Flake Epoxy Floor Sealer: Don't Trip at the Finish Line!

Don't mess it all up by rushing to the end. The topcoat of your clients' new floors is the part that they'll actually feel and see. So, once you've selected your high quality epoxy resin concrete sealer, follow the manufacturer's instructions for mixing and application. Be sure to use a notched squeegee to spread the sealer evenly and avoid pooling. Use a foam roller to roll out any bubbles and achieve a smooth finish.

Patience is key with epoxy. Remind yourself, and your client, to have patience. Allow the sealer to cure and dry fully before allowing foot traffic or heavy use. Regularly maintain and clean your sealed floor to maximize its lifespan and protect your investment. With proper sealing, and a little extra patience at the finish line, your vinyl flake epoxy floor will remain strong, durable, and beautiful for years to come.

Once the sealer has fully dried, carefully inspect the surface for any blemishes or imperfections and sand them down. Then, polish the floor to your desired level of gloss using a floor buffer or polisher (preferably diamond-tipped). With that, you have a beautiful new flake epoxy floor!

Get Certified to Install Vinyl Flake Epoxy Flooring: Epoxy Classes

Invest in yourself, and your business. Flooring certifications are an incredibly beneficial tool in the kit of any contractor. We've designed a program to give aspiring contractors professional training and certification through EpoxyClasses. Our courses cover everything from surface preparation to application and finishing techniques.

You'll learn the best practices and tips from experienced professionals, and have the opportunity to practice your skills in a hands-on setting! Don't miss out on this opportunity to enhance your career - enroll in an EpoxyClasses training course today!

Conclusion

Whether you are a seasoned flooring professional or a DIY enthusiast, vinyl flake epoxy garage flooring is a great service that can transform any flooring business into a competitor in this booming industry. With a little patience, knowledge and investment, you can really start to soar. Don't be intimidated by the process - especially when you can sign up for the Epoxy Classes program! Start your next project today and discover the benefits of vinyl flake epoxy garage flooring!

Contractor or DIY flooring renovator, don't be afraid to reach out at (954) 228-8856 for any on-the-job or general question you have! The EpoxyETC online store will deliver anything and everything epoxy flooring related to your door at competitive rates!

Comments