Efficiently Manage Epoxy Flooring Projects: A Comprehensive Guide

Work smarter, not harder.

Welcome to the ultimate guide on managing epoxy flooring projects efficiently! Epoxy flooring has become the go-to choice for contractors seeking a cost-effective solution to transform their clients' spaces into modern, stylish environments. However, whether you're a veteran contractor or a DIY enthusiast, effective project management plays a vital role in the journey towards success.

In this blog post, we'll provide you with practical tips and tricks to boost the efficiency of your epoxy flooring projects. From measuring square footage to managing labor costs, we'll guide you on how to ensure smooth and successful project execution.

Achieve Success With Knowledge: Efficiently Manage Your Epoxy Flooring Projects

Master Square Footage: Understand the Size of Your Epoxy Flooring Project

One of the most fundamental aspects of efficient epoxy flooring project management is a precise measurement of your project's square footage. Accurate measurement is crucial, because while it's better to have slightly more resin than needed, using excessive amounts is wasteful. On the other hand, running out of resin midway through the project can cause significant disruptions. Take the time to measure diligently, make sure you don't fall short or add unnecessary expenses.

To achieve reliable measurements, remember to be consistent and thorough. Take into account any odd spaces, like alcoves or corners, to get an accurate estimation. Have patience! Measurements can take some time, but what you spend in time in the short term, you'll save in money and headaches later.

Once you have the precise measurement, you can confidently proceed with ordering the materials you need. For reference, RockHard's high quality resin covers an area of 375-400 sq. ft., not counting multiple layers.

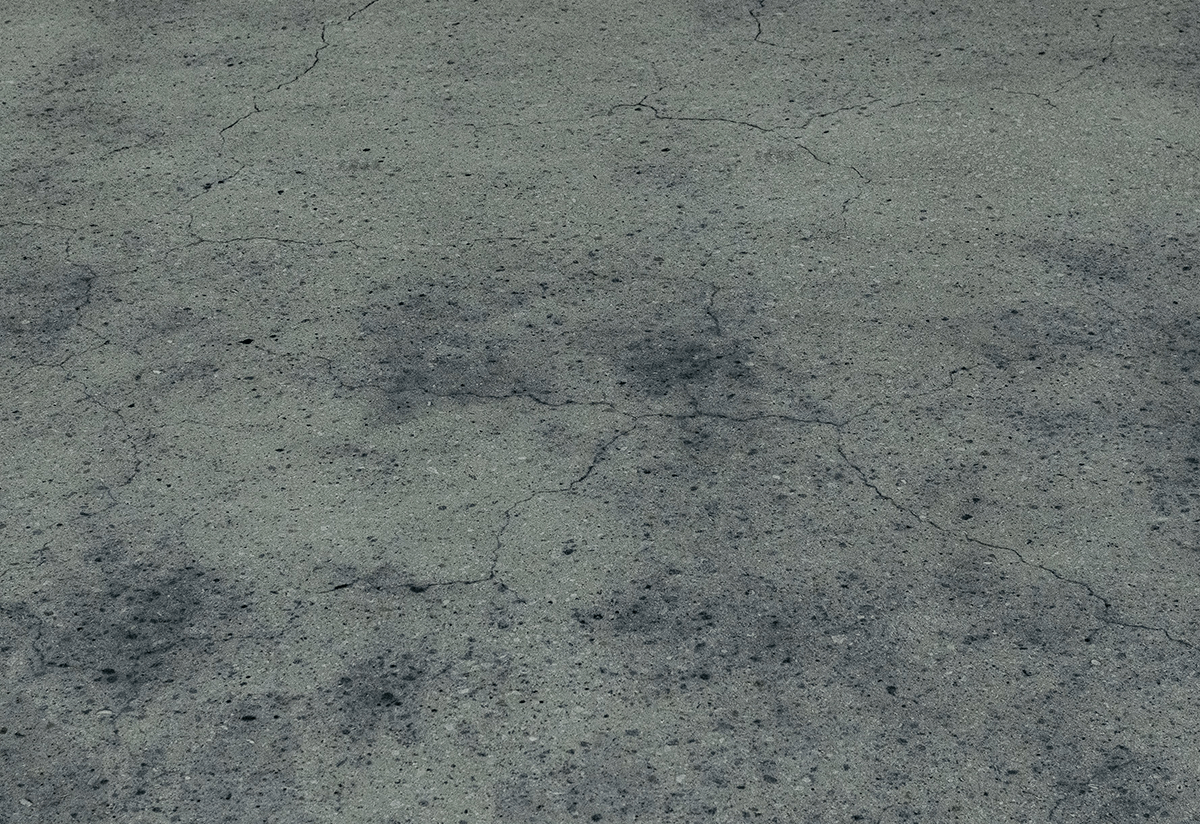

Evaluate Surface Conditions: Flawless Foundation for Your Epoxy Flooring Project

All too often contractors forget to carefully assess the surface for imperfections. If your project involves a concrete foundation, you need to inspect it for moisture, cracks, chips, and any other surface flaws. It's easy to overlook, but a simple check for any problems can save you repairs, or even reinstallation, in the future.

Imperfections, cracks, chips, and unevenness all have the potential to compromise the overall quality of the surface. Epoxy is strong, but a poor surface condition will cause it to premature wear and tear. And it's not just long term cost, either. If your inspection shows there's no cracks or chips, you may be able to entirely skip out on more extensive grinding, which can be both time-consuming and costly in terms of resources.

However, if the concrete surface exhibits damage, you can not cut corners. Neglecting necessary grinding can have long-term financial consequences for both you and your clients, maybe even requiring a complete reinstallation. Similarly, ensuring a level concrete surface is equally important.

Incorporate Labor Costs and Time

Epoxy flooring jobs aren't all that different from any other contracting job. Keep up with your accounting and you'll find profit. That's why it's vital to fully consider labor costs and accurately estimate the required time for the job to get a better picture of your profit margins.

When you start keeping track of these costs, you can even start finding ways to safely maximize project efficiency! For example, you might find it worthwhile to invest in a quick-curing resin like polyaspartic. Polyaspartic resin can cut project times in half, all while maintaining the same strength you expect from epoxy.

Calculating Resource Costs: Essential for Project Success

Just like with labor costs and time, resource costs are a substantial variable in the equation of profit. In flooring projects, this will cover a wide range of items; from physical tools like rollers, resins, and grinders, to resin. Just like with labor and time, accounting for these costs before even an ounce of resin is mixed gives you a super clear picture of what you're working with.

Try to expect the unexpected. With the measurements you've taken, you should know about how much resin you'll need. With your surface inspection, you'll know if you need self-leveling concrete solutions, or a heavy floor grinder. Account, calculate and planning are the keys to a more accurate budget. Once you know the resources you're working with, you can start to work on efficiency, and gain profits!

Taking Environmental Factors into Consideration

When you work on either outdoor or indoor projects, you need to consider any environmental factors that can impact your project timeline. This is part of your time considerations, but it's worth mentioning on its own. Weather conditions, in particular, tend to impact the progress of any flooring project.

Rain delays, extreme temperatures, and even natural disasters all pose challenges. But it's not just weather! Remember to plan around any possible surprises, be prepared to take on surprise delays, and work efficiently around them. Like with any other project, it's impossible to fully expect every surprise. But with a little bit of forethought and planning, you can expect most of them. Check the weather during your project, estimate the duration of each project phase, and make necessary adjustments to stay on track.

And besides just the time considerations, epoxy is susceptible to failing in poor weather conditions. Consider the humidity, heat, or otherwise extreme temperatures and how they might affect your project.

Conclusion

In conclusion, the meticulous estimation of costs is a crucial aspect of achieving profitability and success in your epoxy flooring projects. Each step plays a vital role in creating an accurate cost estimate. This is highly competitive and profitable industry! Beautiful results can take you far, but to really get profits, start planning. Before mixing even an ounce of resin, take the extra time to get your accounting straight.

Do you want more help as an epoxy flooring contractor? Our dedicated technicians are here to assist you. Reach out to us at (954) 228-8856! Remember, cutting corners with low-quality resins and tools is unnecessary. Our EpoxyETC online store provides you with the best resources at affordable rates!

Comments