The Importance of Concrete Moisture Testing

Concrete moisture testing for a better epoxy finish.

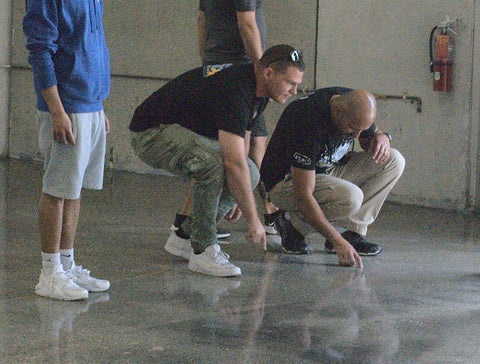

When you're installing new flooring, it's important to understand the moisture levels in your concrete. Skipping this step can lead installers or homeowners alike with weakened finishes on their installation due poor workmanship from improper curing procedures- which means they will need more maintenance over time! This guide will show you your options for quick and easy concrete moisture testing.

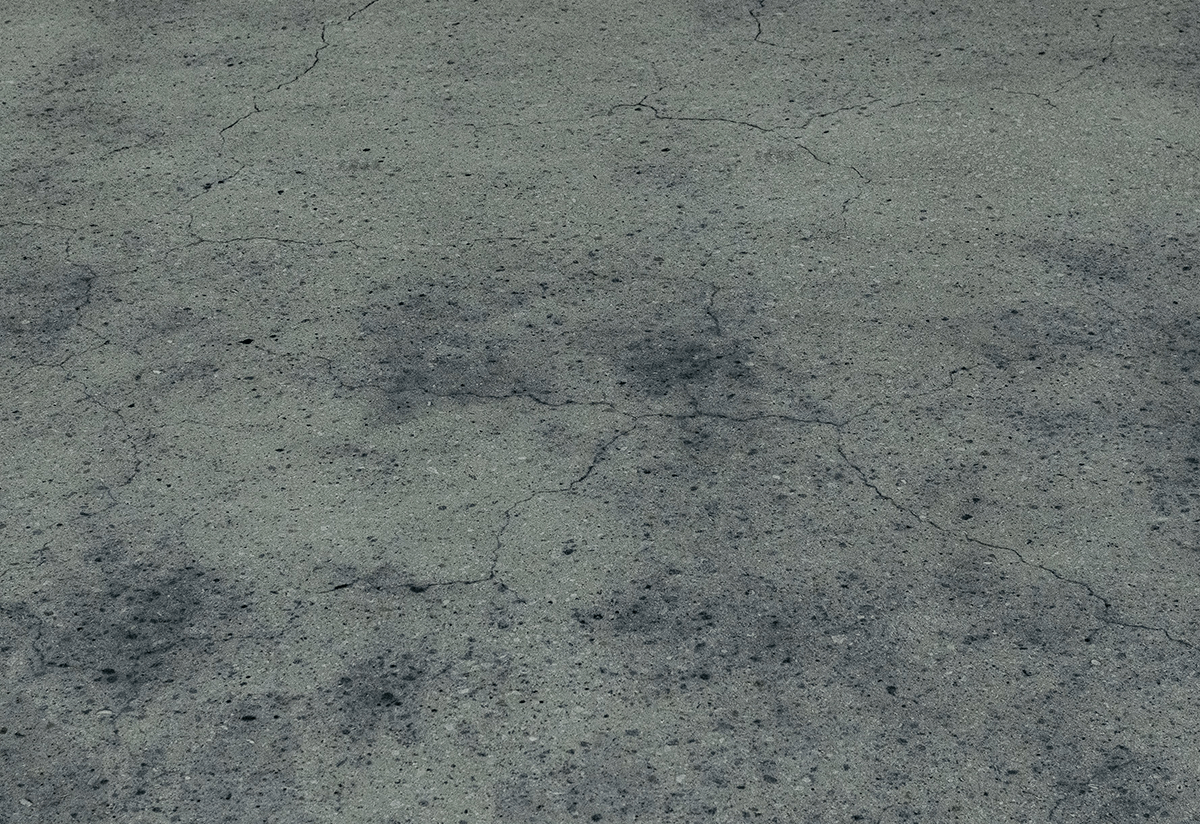

When installing epoxy on concrete, moisture testing should be considered an essential part of your surface preparation. Cutting corners during surface preparation leads to common issues that repair costs in the long term. Untreated moisture especially can cause problems like peeling that will cost more than just investing in testing.

Why You Need Concrete Moisture Testing

When you install epoxy flooring over concrete, it bonds directly to the surface of your foundation. However, if there are high moisture levels in the ground, or water seeps into cracks, then this bond could be compromised. This causes peeled sections that crumble exposed to additional pressures, such as foot traffic.

If you're installing epoxy floors, it's important to test the concrete before beginning work for these reasons. You should also test multiple spots, and atmospheric moisture levels, in order for your installation be stronger and last longer.

How-to: Concrete Moisture Testing

Moisture in concrete is important to be aware of. There are many ways that you can test for it, from probing into the foundation itself, or using surface meters that detect moisture superficially. Any of these methods provide valuable information about what's going on inside the floor’s foundation!

Moisture testing is an essential process that varies in size, thoroughness and accuracy. It pays to be thorough with testing and prioritize accuracy to stave off long term repair costs. You can find the right procedure for you, depending on your site needs, with this guide, and by following industry standards set out by the ASTM.

It is essential to test more than one spot in the concrete for any project. You need to also consider ambient temperature and humidity levels when testing concrete. Being exhaustive with this part of process helps you feel safe installing epoxy and guaranteeing its long term health.

Plastic Sheet Test

The plastic sheet test is a useful method for judging moisture levels. But it's not accurate enough to truly understand how much water you are dealing with, and this could lead your epoxy system failing due exposure down the road!

Calcium Chloride Testing

Moisture in concrete can be tested with a calcium chloride kit. The powder changes color depending on how wet the ground beneath your feet is, making it a very convenient test!

Calcium chloride can be a preliminary procedure to determine if you'll need more invasive testing. The kit tests only on the surface of concrete, so it's important for contractors to make sure their findings match up with other methods before assuming there isn't any moisture.

Non-Invasive Meter Testing

One your best options for moisture testing is non-invasive meter testing, because it uses electricity to measure moisture levels in slabs. This procedure is convenient as no damage needs to occur during testing unlike other methods, like probing.

For most on site needs, you can feel comfortable installing epoxy with just meter testing. This is because it's highly accurate, its only drawback is that it is only a relatively superficial analysis compared to probe testing. If you suspect there might be underlying moisture in your concrete, you may want to invest in probing.

We sell a top of the market non-invasive testing meter on our EpoxyETC website, the Tramex CME5 Concrete Moisture Meter.

In-Situ Probe Testing

Deep moisture in the concrete could lead to problems with your epoxy installation, so it's important that you test for this before applying any new product. This method does require you to damage your concrete base in order to probe, so if you don't suspect deeper moisture issues then you may feel safer going with the meter. You will be rewarded with greater accuracy, though, by probing about 40% of a slab’s depth and testing for moisture.

This is a great opportunity to understand the condition of your concrete better. However, it's important that you know there are risks involved in performing this procedure - for some, these risks are unnecessary. That being said, it never hurts to have accurate information before installing epoxy.

Learn How to Work With Epoxy

Working with epoxy is a hands-on process that requires intimate knowledge of how to install stronger bonds. Online guides are an excellent resource, but nothing beats actually doing the work for yourself! With our 5 day Epoxy Classes program, you can learn the ins and outs of installing epoxy, from beginning to end, with certified professionals. In the class, we cover:

- Surface Preparation (including concrete moisture testing)

- Installing different epoxy floors

- Personalized marketing for your epoxy flooring business

Sign up today to start your career in the flooring industry on the right foot!

Conclusion

Proper installation is the backbone of any new floor. With proper care and maintenance, your clients' floor will be able to withstand years worth or traffic. Moisture testing is an essential step in ensuring that will happen. If you want extra protection while protecting its longevity, you can install a moisture barrier that's sure to keep things in line!

If you have any testing concerns, questions about installing epoxy, or anything else, call and ask our technicians at (954) 287-3797. From testing materials to epoxy resins and more, we have competitive prices on our EpoxyETC online store.

Comments