How To Prepare Concrete For Epoxy Coatings (2021)

There are three main ways to prepare concrete for epoxy:

- Acid Etching

- Diamond Grinding

- Shot Blasting

Acid Etching

When it comes to applying an epoxy floor, going the DIY route is always a viable option. With your surface preparation, acid etching is the best option for a DIYer. Acid etching is perfect for the DIYer because it does not require any machinery or technical skill to apply.

Acid etching is done through the use of hydrochloric acid. Hydrochloric acid is the go-to chemical for acid etching, but it can have potential harmful effects to the environment. When using this chemical, be sure that any and all pets are away from the area to ensure their safety.

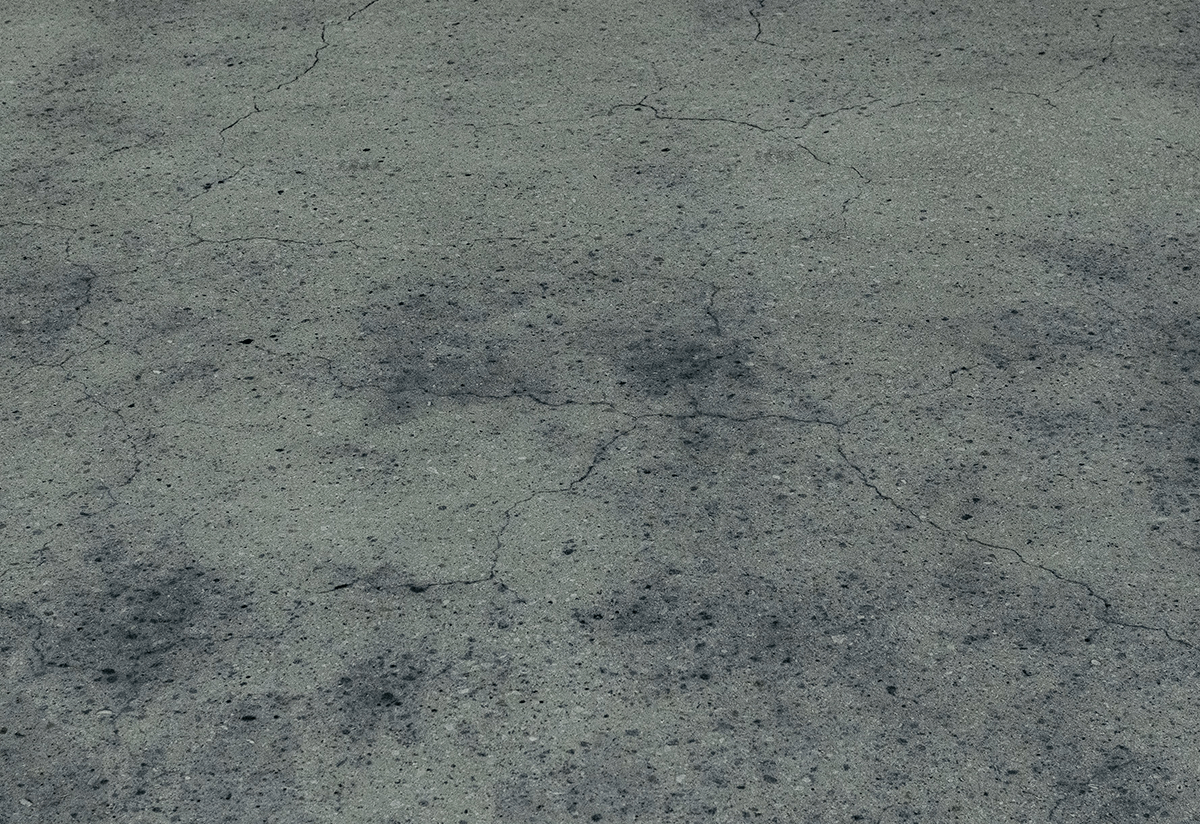

Before beginning acid etching or any concrete preparation, it is important that you fill any cracks or holes in the concrete surface with crack filler. We recommend this one.

After filling in all of the cracks and holes in the surface, be sure to remove any mastic or glues from the surface. Acid etching will not eat through any of those materials so it is imperative that they are removed before the preparation begins.

Once the floor cracks are filled and grime removed, spread the acid etching solution over the surface and spread it out evenly with a stiff-bristle broom. Let the acid sit on the concrete for 10 minutes, then pressure wash the surface and vacuum the leftover materials after everything has dried.

Diamond Grinding

If you are a concrete professional, it is likely that you will have a grinding machine to make surface preparation a much quicker and easier process. At EpoxyETC, we offer handheld, walk-behind, and ride-on grinding solutions. Check out this article to learn the difference and benefits of each option.

A concrete grinding machine uses diamond grit blades to profile the surface so that the epoxy can adhere to the surface properly. As a good rule of thumb, the lower the diamond grit, the rougher the surface is going to be. Consult the manufacturer’s information labels on your coatings to inform you on what level of CSP you will need.

If you are a homeowner, we recommend that you seek out a concrete professional if you lack the construction experience needed to operate one of these machines effectively. We recommend using EpoxyNetwork to find a contractor near you!

Shot Blasting

Out of the three surface preparation techniques, shot blasting is by-far the one that requires the most technical skill and is least suitable for DIYers and nonprofessionals. Shot blasting a concrete surface is an age old tradition so there are many styles and techniques.

Using a shot blasting machine requires a large amount of technical skill, which makes this a difficult technique if you are not a skilled professional. Additionally, if used incorrectly, a shot blasting machine can cause more damage to the floors than good. With this technique, the floor will be removed of all impurities and imperfections so there will not be much additional cleaning needed.

Like using a diamond grinding machine, a shot blaster will profile the floor to the appropriate level for the coating you are going to apply. It is important that you do not over blast the floor as it can become too smooth for an epoxy coating to adhere.

Conclusion

Regardless of the surface preparation technique that you choose, you will be able to craft the perfect surface for a coating to be applied to. If you have any additional questions or need advice on which technique will be appropriate for your scenario, feel free to contact one of our epoxy specialists at (954)-799-6359.

Comments